| [1] |

T. DebRoy et al., "Scientific, technological and economic issues in metal printing and their solutions," Nature Materials, vol. 18, no. 10, pp. 1026-1032, 2019/10/01 2019, doi: 10.1038/s41563-019-0408-2.

|

| [2] |

D. Gu, X. Shi, R. Poprawe, D. L. Bourell, R. Setchi, and J. Zhu, "Material-structureperformance integrated laser-metal additive manufacturing," Science, vol. 372, no. 6545, p. eabg1487, 2021/05/28 2021, doi: 10.1126/science.abg1487.

|

| [3] |

J. Bonnín Roca, P. Vaishnav, E. R. H. Fuchs, and M. G. Morgan, "Policy needed for additive manufacturing," Nature Materials, vol. 15, no. 8, pp. 815-818, 2016/08/01 2016, doi: 10.1038/nmat4658.

|

| [4] |

S. Ashley. (1995, 1995/07//) Rapid prototyping is coming of age. Mechanical EngineeringCIME [Cover story]. 62+. Available: https://link.gale.com/apps/doc/A17261601/AONE?u=anon~4f2efd98&sid=googleScholar &xid=a54e7edb

|

| [5] |

T. DebRoy, T. Mukherjee, H. L. Wei, J. W. Elmer, and J. O. Milewski, "Metallurgy, mechanistic models and machine learning in metal printing," Nature Reviews Materials, vol. 6, no. 1, pp. 48-68, 2021/01/01 2021, doi: 10.1038/s41578-020-00236-1.

|

| [6] |

S. A. Khairallah, A. T. Anderson, A. Rubenchik, and W. E. King, "Laser powder-bed fusion additive manufacturing: Physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones," Acta Materialia, vol. 108, pp. 36-45, 2016/04/15/2016, doi: https://doi.org/10.1016/j.actamat.2016.02.014.

|

| [7] |

A. Khairallah Saad et al., "Controlling interdependent meso-nanosecond dynamics and defect generation in metal 3D printing," Science, vol. 368, no. 6491, pp. 660-665, 2020/05/08 2020, doi: 10.1126/science.aay7830.

|

| [8] |

W. E. King et al., "Observation of keyhole-mode laser melting in laser powder-bed fusion additive manufacturing," Journal of Materials Processing Technology, vol. 214, no. 12, pp. 2915-2925, 2014/12/01/2014, doi: https://doi.org/10.1016/j.jmatprotec.2014.06.005.

|

| [9] |

R. Cunningham et al., "Keyhole threshold and morphology in laser melting revealed by ultrahigh-speed x-ray imaging," Science, vol. 363, p. 849, 2019.

|

| [10] |

C. Zhao et al., "Critical instability at moving keyhole tip generates porosity in laser melting," Science, vol. 370, no. 6520, p. 1080, 2020, doi: 10.1126/science.abd1587.

|

| [11] |

M. Bayat et al., "Keyhole-induced porosities in Laser-based Powder Bed Fusion (L-PBF) of Ti6Al4V: High-fidelity modelling and experimental validation," Additive Manufacturing, vol. 30, p. 100835, 2019/12/01/2019, doi: https://doi.org/10.1016/j.addma.2019.100835.

|

| [12] |

M. Grasso and B. M. Colosimo, "Process defects and in situ monitoring methods in metal powder bed fusion: a review," Meas. Sci. Technol., vol. 28, 2017.

|

| [13] |

D. Y. Kononnko, V. Nikonova, M. Seleznev, J. van den Brink, and D. Chernyavsky, "An in situ crack detection approach in additive manufacturing based on acoustic emission and machine learning," Additive Manufacturing Letters, vol. 5, p. 100130, 2023/04/01/2023, doi: https://doi.org/10.1016/j.addlet.2023.100130.

|

| [14] |

B. J. Simonds et al., "Time-Resolved Absorptance and Melt Pool Dynamics during Intense Laser Irradiation of a Metal," Physical Review Applied, no. 10, p. 044061, 2018.

|

| [15] |

M. Grasso, A. Remani, A. Dickins, B. M. Colosimo, and R. K. Leach, "In-situ measurement and monitoring methods for metal powder bed fusion: an updated review," Measurement Science and Technology, vol. 32, no. 11, p. 112001, 2021/07/15 2021, doi: 10.1088/1361-6501/ac0b6b.

|

| [16] |

C. Wang, X. P. Tan, S. B. Tor, and C. S. Lim, "Machine learning in additive manufacturing: State-of-the-art and perspectives," Additive Manufacturing, vol. 36, p. 101538, 2020/12/01/2020, doi: https://doi.org/10.1016/j.addma.2020.101538.

|

| [17] |

J. Qin et al., "Research and application of machine learning for additive manufacturing," Additive Manufacturing, vol. 52, p. 102691, 2022/04/01/2022, doi: https://doi.org/10.1016/j.addma.2022.102691.

|

| [18] |

L. Scime and J. Beuth, "Anomaly detection and classification in a laser powder bed additive manufacturing process using a trained computer vision algorithm," Additive Manufacturing, vol. 19, pp. 114-126, 2018/01/01/2018, doi: https://doi.org/10.1016/j.addma.2017.11.009.

|

| [19] |

B. Mondal, T. Mukherjee, and T. DebRoy, "Crack free metal printing using physics informed machine learning," Acta Materialia, vol. 226, p. 117612, 2022/03/01/2022, doi: https://doi.org/10.1016/j.actamat.2021.117612.

|

| [20] |

R. Liu, S. Liu, and X. Zhang, "A physics-informed machine learning model for porosity analysis in laser powder bed fusion additive manufacturing," The International Journal of Advanced Manufacturing Technology, vol. 113, no. 7, pp. 1943-1958, 2021/04/01 2021, doi: 10.1007/s00170-021-06640-3.

|

| [21] |

S. A. Shevchik, C. Kenel, C. Leinenbach, and K. Wasmer, "Acoustic emission for in situ quality monitoring in additive manufacturing using spectral convolutional neural networks," Additive Manufacturing, vol. 21, pp. 598-604, 2018.

|

| [22] |

J. R. Tempelman et al., "Detection of keyhole pore formations in laser powder-bed fusion using acoustic process monitoring measurements," Additive Manufacturing, vol. 55, p. 102735, 2022/07/01/2022, doi: https://doi.org/10.1016/j.addma.2022.102735.

|

| [23] |

V. Pandiyan et al., "Deep learning-based monitoring of laser powder bed fusion process on variable time-scales using heterogeneous sensing and operando X-ray radiography guidance," Additive Manufacturing, vol. 58, p. 103007, 2022/10/01/2022, doi: https://doi.org/10.1016/j.addma.2022.103007.

|

| [24] |

S. Gorgannejad et al., "Localized Keyhole Pore Prediction during Laser Powder Bed Fusion via Multimodal Process Monitoring and X-ray Radiography," Additive Manufacturing, p. 103810, 2023/10/04/2023, doi: https://doi.org/10.1016/j.addma.2023.103810.

|

| [25] |

D. R. Gunasegaram et al., "Machine learning-assisted in-situ adaptive strategies for the control of defects and anomalies in metal additive manufacturing," Additive Manufacturing, vol. 81, p. 104013, 2024/02/05/2024, doi: https://doi.org/10.1016/j.addma.2024.104013.

|

| [26] |

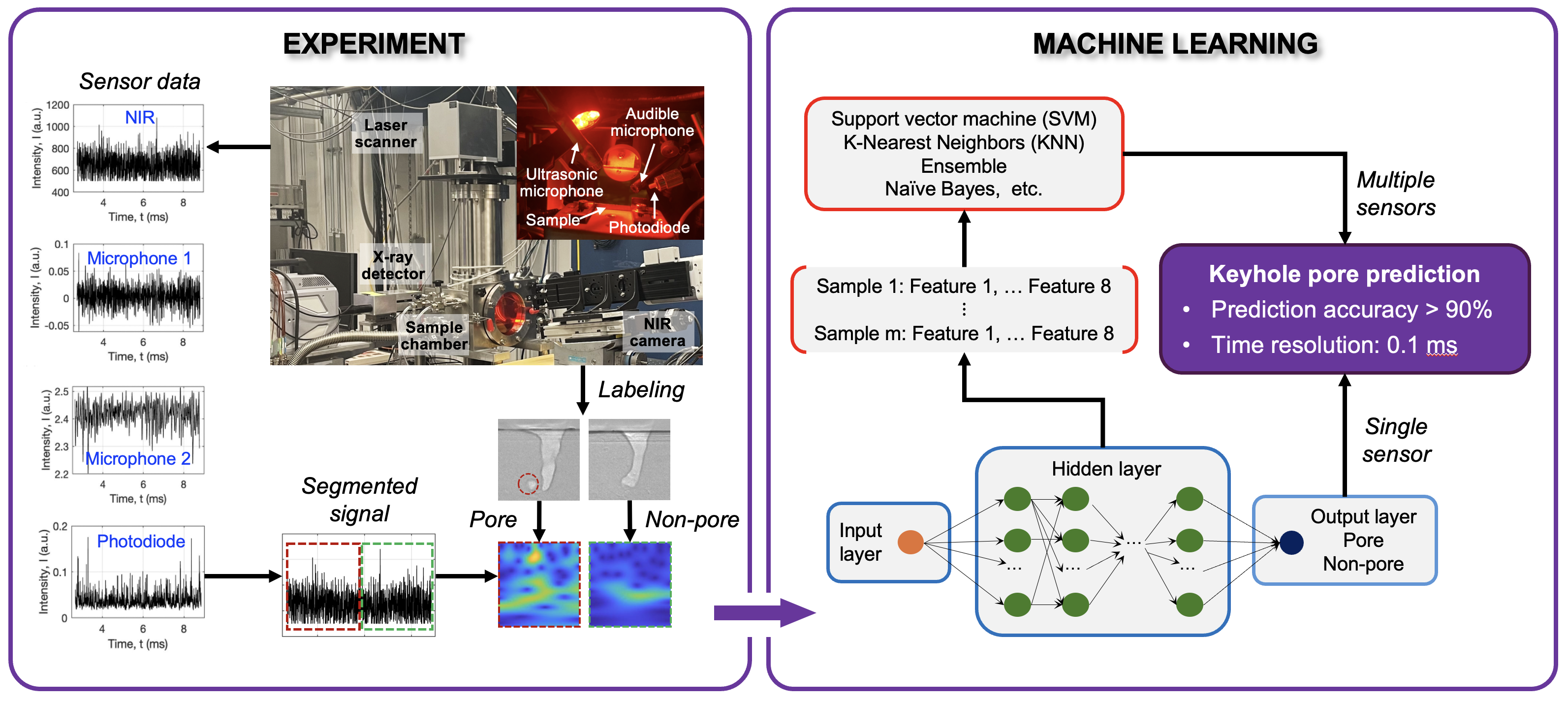

Z. Ren et al., "Machine learning-aided real-time detection of keyhole pore generation in laser powder bed fusion," Science, vol. 379, no. 6627, pp. 89-94, 2023/01/06 2023, doi: 10.1126/science.add4667.

|

| [27] |

C. Zhao et al., "Real-time monitoring of laser powder bed fusion process using high-speed X-ray imaging and diffraction," Scientific Reports, vol. 7, 2017.

|

| [28] |

N. D. Parab et al., "Ultrafast X-ray imaging of laser-metal additive manufacturing processes," Journal of synchrotron radiation, vol. 25, no. 5, pp. 1467-1477, 2018.

|

| [29] |

C. Zhao et al., "Bulk-Explosion-Induced Metal Spattering During Laser Processing," Physical Review X, vol. 9, no. 2, p. 021052, 06/14/2019, doi: 10.1103/PhysRevX.9.021052.

|

| [30] |

Z. Qibin and Z. Liqing, "ECG Feature Extraction and Classification Using Wavelet Transform and Support Vector Machines," in 2005 International Conference on Neural Networks and Brain, 13-15 Oct. 2005, vol. 2, pp. 1089-1092, doi: 10.1109/ICNNB.2005.1614807.

|

| [31] |

Q. Luo, L. Yin, T. W. Simpson, and A.M. Beese. "Effect of processing parameters on pore structures, grain features, and mechanical properties in Ti-6Al-4V by laser powder bed fusion." Additive Manufacturing, vol. 56, Aug. 2022: 102915, doi: https://doi.org/10.1016/j.jmst.2024.01.010.

|

| [32] |

F. N. Iandola, S. Han, M. W. Moskewicz, K. Ashraf, W. J. Dally, and K. Keutzer, “SqueezeNet: AlexNet-level accuracy with 50x fewer parameters and< 0.5 MB model size,” arXiv preprint, 2016, arXiv:1602.07360, doi: https://doi.org/10.48550/arXiv.1602.07360

|

| [33] |

P. Bidare, R. R. J. Maier, R. J. Beck, J. D. Shephard, and A. J. Moore, "An openarchitecture metal powder bed fusion system for in-situ process measurements," Additive Manufacturing, vol. 16, pp. 177-185, 2017/08/01/2017, doi: https://doi.org/10.1016/j.addma.2017.06.007.

|

| [34] |

W. Tan, N. S. Bailey, and Y. C. Shin, "Investigation of keyhole plume and molten pool based on a three-dimensional dynamic model with sharp interface formulation," Journal of Physics D: Applied Physics, vol. 46, no. 5, p. 055501, 2013/01/04 2013, doi: 10.1088/0022- 3727/46/5/055501.

|

| [35] |

D. Farson and K. Kim, "Generation of optical and acoustic emissions in laser weld plumes," Journal of applied physics, vol. 85, no. 3, pp. 1329-1336, 1999.

|

| [36] |

I. Bitharas, N. Parab, C. Zhao, T. Sun, A. D. Rollett, and A. J. Moore, "The interplay between vapour, liquid, and solid phases in laser powder bed fusion," Nature Communications, vol. 13, no. 1, p. 2959, 2022/05/26 2022, doi: 10.1038/s41467-022-30667-z.

|

| [37] |

S. A. Khairallah, T. Sun, and B. J. Simonds, "Onset of periodic oscillations as a precursor of a transition to pore-generating turbulence in laser melting," Additive Manufacturing Letters, vol. 1, p. 100002, 2021/12/01/2021, doi: https://doi.org/10.1016/j.addlet.2021.100002.

|

| [38] |

Y. Sun, S. et al, Direct mechanistic connection between acoustic signals and melt pool morphology during laser powder bed fusion. Applied Physics Letters, 2022, 125(3).

|

| [39] |

V. V. Semak, J. A. Hopkins, M. H. McCay, and T. D. McCay, "Melt pool dynamics during laser welding," Journal of Physics D: Applied Physics, vol. 28, no. 12, pp. 2443-2450, 1995/12/14 1995, doi: 10.1088/0022-3727/28/12/008.

|

| [40] |

S. C. Olhede, and A. T. Walden. “Generalized morse wavelets,” IEEE Transactions on Signal Processing, Vol. 50, No. 11, 2002, pp. 2661-2670. doi: 10.1109/TSP.2002.804066.

|

| [41] |

Morse Wavelets, https://www.mathworks.com/help/wavelet/ug/morse-wavelets.html, MathWorks, Oct. 16th, 2024.

|

| [42] |

Pretrained Deep Neural Networks, https://www.mathworks.com/help/deeplearning/ug/pretrained-convolutional-neuralnetworks.html, MathWorks, Oct. 16th, 2024.

|

| [43] |

S. Saha, Z. Gan, L. Cheng, J. Gao, O. L. Kafka, X. Xie, H. Li, M. Tajdari, H. A. Kim and W. K. Liu. Hierarchical deep learning neural network (HiDeNN): an artificial intelligence (AI) framework for computational science and engineering. Computer Methods in Applied Mechanics and Engineering, 2021, 373, 113452.

|

下载:

下载:

京公网安备 11010502036328号 京ICP备17033152号

京公网安备 11010502036328号 京ICP备17033152号