Annual research review of perovskite solar cells in 2023

doi: 10.1088/2752-5724/ad42ba

-

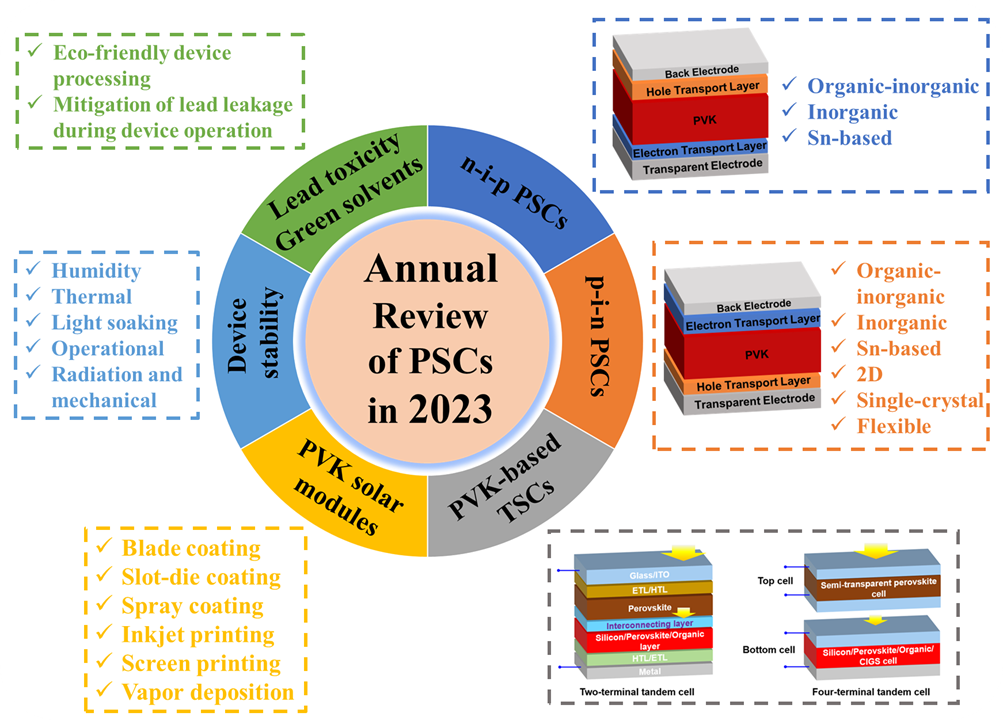

Abstract: AbstractPerovskite (PVK) solar cells (PSCs) have garnered considerable research interest owing to their cost-effectiveness and high efficiency. A systematic annual review of the research on PSCs is essential for gaining a comprehensive understanding of the current research trends. Herein, systematic analysis of the research papers on PSCs reporting key findings in 2023 was conducted. Based on the results, the papers were categorized into six classifications, including regular n-i-p PSCs, inverted p-i-n PSCs, PVK-based tandem solar cells, PVK solar modules, device stability, and lead toxicity and green solvents. Subsequently, a detailed overview and summary of the annual research advancements within each classification were presented. Overall, this review serves as a valuable resource for guiding future research endeavors in the field of PSCs.

-

Key words:

- perovskite solar cells /

- annual review /

- systematic review

-

Figure 4. (a) Efficiencies of small cells (red), mini-modules (blue), and submodules (black) recorded in 2023 [5, 11]. (b) ETL initiated disordered growth of PVK films at the buried interface. Reproduced from [2], with permission from Springer Nature. (c) Schematic of the thermodynamic driving force and the kinetics of the oriented nucleation of PVK films. Reproduced from [1], with permission from Springer Nature.

Figure 5. (a) Energy levels of perovskite, PbS, Cu2S and spiro-OMeTAD and (b) best J-V data tested in reverse (RS) and forward (FS) scans of PSCs of pristine PSC device and treated by Cu-HBT after thermal treatment; (a), (b) [39] John Wiley & Sons. © 2023 Wiley-VCH GmbH. (c) The energy levels of fabricated CsPbI2Br-based PSCs and (d) J-V characteristics of devices with different HTL; (c), (d) [42] John Wiley & Sons. © 2023 Wiley-VCH GmbH. (e) The schematic energy level alignment of TiO2, perovskite films, HTL and Au electrode and (f) J-V curves under 100 mW cm−2 irradiation (AM 1.5) condition. (e), (f) [38] John Wiley & Sons. © 2023 Wiley-VCH GmbH.

Figure 6. (a) Cross-sectional SEM image. (b) J-V curves of the highest-performing PSCs. (c) Electrical conductivity of the HTM films of spiro-OMeTAD doped by Li/Co/t-BP and DPI-TPFB. The inset shows the undoped spiro-OMeTAD film. (a)-(c) [55] John Wiley & Sons. © 2023 Wiley-VCH GmbH. (d) Schematic of the interaction between transDACH and CsSnI3. (e) Electrostatic potential surfaces of CsSnI3 and CsSnI3-transDACH (negative and positive electrostatic potentials are indicated in red and blue, respectively). (f) J-V curves of champion CsSnI3-based PSCs doped with various transDACH contents. (d)-(f) [27] John Wiley & Sons. © 2022 Wiley-VCH GmbH. (g) SEM images of pristine and Bi3+-doped CsSnI3 PVK films. (h) J-V curves of PSCs with pristine and Bi3+-doped CsSnI3 PVKs. (g), (h) Reprinted from [56], © 2023 Elsevier B.V. All rights reserved.

Figure 7. Representative proceedings on Pb-based inverted PSCs in 2023 [60-65]. (a), (c) From [60]. Reprinted with permission from AAAS. From [61]. Reprinted with permission from AAAS. (b), (d)-(f) Reproduced from [62], with permission from Springer Nature. Reproduced from [63], with permission from Springer Nature. Reproduced from [64]. CC BY 4.0. Reproduced from [65], with permission from Springer Nature.

Figure 8. (a) Energy diagram of PSCs (with MMI treatment) and (b) J-V performance of PSCs with and without MMI treatment and hysteresis. [128] John Wiley & Sons. © 2023 Wiley-VCH GmbH. (c) Schematic illustration of the inverted IPSCs (with ABA treated) and (d) J-V curves of the champion control and ABA treated p-i-n IPSCs under one-sun illumination. [129] John Wiley & Sons. © 2023 Wiley-VCH GmbH. (e) Energy level structure diagram of IPSC and (f) J-V curves of control device and ISE-device. [126] John Wiley & Sons. © 2023 Wiley-VCH GmbH.

Figure 9. (a) DFT calculations of optimized slab models for pristine Sn PVK with VSn and VI defects and In- and Br-co-doped Sn PVK (VSn and VI are the Sn and I vacancies, respectively). (b) Summarized PCEs and Voc values for the reported advanced TPSCs. (a), (b) [138] John Wiley & Sons. © 2023 Wiley-VCH GmbH. (c) Comparison of the FFs of 0.05-AET TPSC with previously reported TPSCs, revealing the highest FF achieved. High-resolution XPS spectra showing the Sn 3d regions of (d) control and (e) 0.05-AET Sn-based PVKs. (f) GIWAXS patterns of 0.05-AET Sn-based PVK films. (c)-(f) [136] John Wiley & Sons. © 2023 Wiley-VCH GmbH.

Figure 10. (a) Characteristic J-V curves of TPSCs incorporated with different ETLs (four regional isomers of DCBA, namely trans-2, trans-3, trans-4, and e). [140] John Wiley & Sons. © 2023 Wiley-VCH GmbH. (b) Characteristic J-V curves of TPSCs incorporated with C60BB and C70BB. Reprinted with permission from [141]. Copyright (2023) American Chemical Society. (c) Energy diagram of Sn PSCs incorporated with SnOx HTL. Reprinted with permission from [142]. Copyright (2023) American Chemical Society (d) J-V curves of the devices made of PQx, TQx, PQxD, and TQxD. [143] John Wiley & Sons. © 2023 Wiley-VCH GmbH. (e) SAM-embedded NiOx for oxidation suppression. (f) Contact potential difference for NiOx and 2PADBC-embedded NiOx films. (e), (f) [144] John Wiley & Sons. © 2023 Wiley-VCH GmbH. (g) Structure of Sn-based PSCs inserted with Sn metal on both the upper and lower surfaces of the PVK layer. [145] John Wiley & Sons. © 2023 Wiley-VCH GmbH.

Figure 11. (a) J-V characteristic curves of the CsSnI3 solar cells based on without CBZ and with CBZ. Insets: SEM Images the pristine CsSnI3 and CsSnI3:CBZ films. [125] John Wiley & Sons. © 2023 Wiley-VCH GmbH. (b) Photocurrent density-voltage curves of the optimized C-CsSnI3 and S-CsSnI3 PSCs. Insets: SEM images of S-CsSnI3 and C-CsSnI3 films. Reproduced from [151] with permission from the Royal Society of Chemistry.

Figure 12. (a) Strong hydrogen bonding (O−H···O) linking adjacent spacing sheets in (GABA)2MA3Pb4I13 crystal, which enhanced the PCE of the corresponding 2D RP PSCs. [160] John Wiley & Sons. © 2023 Wiley-VCH GmbH. (b) Devices based on two unique semiconductor spacers with strong interactions, with PCEs increasing considerably from 15.66% to 18.56%. [162] John Wiley & Sons. © 2023 Wiley-VCH GmbH. (c) Chemical structure and DFT-calculated energy levels of the BPhMA spacer. Reproduced with permission. (d) Chemical structure and DFT-calculated energy levels of the BThMA spacer. (c), (d) [163] John Wiley & Sons. © 2023 Wiley-VCH GmbH. (e) Synthetic routes of two organic spacer cations, BTFAI and TTFAI. [164] John Wiley & Sons. © 2023 Wiley-VCH GmbH. (f) Schematic of (A(FA)3Pb4I13)-based DJ 2D PVKs and chemical structure of all-organic spacers studied herein. [165] John Wiley & Sons. © 2023 Wiley-VCH GmbH.

Figure 13. (a) Hypothesized crystallization mechanism of BDA/FA, BDA/FA-MACl, and BDA/FA-MACl & PbCl2 films. BDA/FA film comprises a δ phase and low-dimensional phase, while BDA/FA-MACl film gradually exhibits the appearance of both δ and low-dimensional phases as chlorine evaporates. BDA/FA-MACl & PbCl2 film, grown epitaxially under the induction of preformed seeds, yields a highly robust α phase 2D PVK. [166] John Wiley & Sons. © 2023 Wiley-VCH GmbH. (b) Schematic of an n = 5 RP PVK (PEA)2MA4Pb5I16 film and corresponding charged defect sites in PVKs. (c) PBN molecular structure and possible function of each functional group, including the benzene group (green), nitrone group (blue), and t-butyl group (purple). (b), (c) [167] John Wiley & Sons. © 2023 Wiley-VCH GmbH.

Figure 14. Niche research directions of 2D PVKs. (1) Large-area fabrication of 2D PSMs: schematic of the PVK coating process, optical image of the large-area FA0.4MA0.6−xGAxPbI3 PVK film prepared on the SnO2/CATNI sample, and front view optical images of the planar n-i-p PSMs. [170] John Wiley & Sons. © 2023 Wiley-VCH GmbH. (2) New fabrication technique of imprinting transfer: schematic of the solvent-free transfer-imprinting-assisted growth process. Reprinted with permission from [114]. Copyright (2023) American Chemical Society. (3) Construction of 2D/3D/2D PVKs: schematic of the device structure. [171] John Wiley & Sons. © 2023 Wiley-VCH GmbH. (4) Design of a novel carrier transport layer: the proposed passivation mechanism of PVKs influenced by different polymers. [68] John Wiley & Sons. © 2023 Wiley-VCH GmbH. (5) Machine learning-enhanced high-throughput exploration: summary of the design of experimental approach for 2D PVKs. [172] John Wiley & Sons. © 2023 The Authors. Advanced Energy Materials published by Wiley-VCH GmbH.

Figure 16. (a) Schematic of the blade coating method. Reproduced from [235], with permission from Springer Nature. (b) Illustration of the chelation of the LCMs (in the HTL) with Pb2+ ions at the bottom side of the PVK films. (c) I-V curves of the control and target modules. (b), (c) From [245]. Reprinted with permission from AAAS. (d) (Ⅰ) Electric dipole moment and (Ⅱ) polar solvation energy of DMSO, NMP, and DMI. (e) Schematic of the nucleation and crystallization of (Ⅰ) DMF/DMSO, (Ⅱ) 2-Me/NMP, and (Ⅲ) 2-Me/DMI complexes based on LaMer mechanism. (d), (e) [246] John Wiley & Sons. © 2023 The Authors. Advanced Energy Materials published by Wiley-VCH GmbH. (f) Schematic of the crystallization of control and double-chain QACS-based PVK. (g) I-V curves of the champion DMDO module. The left inset shows the steady-state power output and current of the champion module. The right inset shows an image of the module. (f), (g) Reprinted from [247], © 2023 Elsevier Inc. (h) Structure of the PVK bifacial module. P1, P2, and P3 are the three scribing lines in thin-film modules connected in series. (i) An image of the PVK bifacial module from the front and rear sides with Ag grids, respectively. The aperture area size of the module is 39 mm × 55 mm. (j) I-V curves of the champion bifacial module with light coming from the front and rear sides. (h)-(j) Reproduced from [234], with permission from Springer Nature.

Figure 17. (a) Schematic of slot-die coating. [251] John Wiley & Sons. © 2023 Wiley-VCH GmbH. (b) Comparison of PVK layer homogeneity for two precursor inks: 92-vol% 2-Me/8-vol% NMP/0-vol% ACN and 46-vol% 2-Me/8-vol% NMP/46-vol% mixed inks. (Ⅰ) Images of the as-coated wet PVK film; (Ⅱ) sketches of the meniscus and resulting ribbing phenomena are illustrated; and (Ⅲ) images of the annealed PVK film and corresponding top-view (above) and cross-sectional (below) SEM images. (c) I-V curves of a PSM; the inset is a corresponding optical image. (b), (c) Reproduced from [249]. CC BY 4.0. (d) Schematic of the locally supersaturated PVK precursor inks. (e) Changes in surface tension and dynamic viscosity of PVK precursor inks with different DCB contents. (f) Contact angles of the corresponding PVK precursor ink with different DCB contents measured on the NiO-coated ITO substrate. (g) In situ optical microscopy images with a scale bar 100 μm showing the crystal growth process in conventional PVK ink (CPI) and LSPI-based PVK films (t0 represents the PVK wet film state and tn represents the initiation of nucleation and grain growth). (d)-(g) [250] John Wiley & Sons. © 2023 Wiley-VCH GmbH. (h) DFT calculations of FABP-treated films. Yellow (cyan) denotes the charge accumulation (losses) of the FAPbI3 surface with (Ⅰ) FA vacancy passivated by pentafluoroanilinium cation; (Ⅱ) I vacancy passivated by pentafluorobenzyl phosphonate anion; and (Ⅲ) Pb vacancy passivated by pentafluoroanilinium cation. (i) I-V curve of the best-performing passivated PSMs (inset: PSM with 13 subcells). (h), (i) [251] John Wiley & Sons. © 2023 Wiley-VCH GmbH.

Figure 18. (a) Schematic of spraying coating. Reprinted from [236], © 2022 Elsevier B.V. All rights reserved. (b) Schematic of the drying behavior of droplets sprayed in dry air and humid air. (c) Optical microscopy (OM) images of the films prepared by spraying the trace solution on CsI/PbI2 film in dry and humid air; insets are the corresponding OM images of freshly formed films without annealing after complete spraying. (b), (c) Reprinted from [253], © 2023 Elsevier Ltd. All rights reserved (d) Schematic of inkjet printing. [237] John Wiley & Sons. © 2021 Wiley-VCH GmbH. (e) Image of the aged PVK precursor inks. (f) Top-view and cross-sectional SEM images of the PVK layer fabricated on top of the m-TiO2 layer using (Ⅰ), (Ⅲ) 1.8 M DMF- and (Ⅱ), (IV) 0.8 M GVL-based PVK precursor inks. (e), (f) Reproduced from [254]. CC BY 4.0. (g) Diagram of the screen printing method for the deposition of PVK films. Reproduced from [238], with permission from Springer Nature. (h) Schematic of the growth process of the PVK NCs in the mesoporous layer based on (Ⅰ) MAAc and (Ⅱ) MAAc/MAPa solvent systems. [255] John Wiley & Sons. © 2023 Wiley-VCH GmbH.

Figure 19. (a) Schematic of CVD. (b) Schematic of spontaneous nucleation crystallization and recrystallization processes. (c) In situ XRD patterns of PVK films obtained during the treatment. (a)-(c) [256] John Wiley & Sons. © 2023 Wiley-VCH GmbH. (d) SEM images (cross-section images on top and top-view images on bottom). PbI2 film deposited by (Ⅰ) evaporation and (Ⅱ) solution process. PVK film deposited by (Ⅲ) evaporation and (IV) solution process. [257] John Wiley & Sons. © 2023 Wiley-VCH GmbH. (e) Schematic of the ETL/PVSK interface passivation with H2KNO3S. (f) Schematic of the nucleation and growth of PVKs. (g) Schematic of the seed growth of PVKs. (e)-(g) [258] John Wiley & Sons. © 2023 The Authors. Advanced Energy Materials published by Wiley-VCH GmbH.

Figure 20. (a) Water and oxygen causing degradation in formamidinium-based halide PVKs. Reproduced from [287]. CC BY 4.0. (b) Encapsulation structures of PSCs with (left) and without the external gap (right). Reprinted from [278], © 2023 Elsevier Inc. (c) Schematics representing the thin-film single-junction PSC architecture before final encapsulation into a module and strategies to circumvent the hygroscopic nature of MHP and hole/electron contacts. [289] John Wiley & Sons. © 2023 Wiley-VCH GmbH. (d) Structural transformation of FAPbI3 under humid conditions. Reprinted with permission from [290]. Copyright (2022) American Chemical Society.

Figure 21. (a) Schematic of the 2D PVK film formation process using HAc. Reprinted with permission from [297]. Copyright (2023) American Chemical Society. (b) Illustrations of the tensile/compressive strains of PVK film and their effects. Reprinted with permission from [298]. Copyright (2023) American Chemical Society. (c) Proposed scheme of enhanced ion exchange for thermally induced halide mixing to form mixed-halide PVKs. The scheme shows the passivation of trap states at grain boundaries by BMIMBF4. Reprinted with permission from [270]. Copyright (2023) American Chemical Society. (d) Scheme of the unencapsulated PSCs (left), PSCs with UV resin encapsulation (middle), and PSCs with CFDP encapsulation (right). Reproduced from [299]. CC BY 4.0.

Figure 22. (a) HOMO energies of organic HTLs measured by UPS, where the VBM positions of PVKs are marked as dashed lines. (b) Schematic of reactions between I2 and HTLs with different HOMO levels. (a), (b) Reprinted with permission from [303]. Copyright (2023) American Chemical Society. (c) Thermodynamic origin of the photostability of the 2D PVK PEA2Pb(I1−xBrx)4. Reproduced from [304]. CC BY 4.0.

Figure 23. (a) Chemical structures of P1 and P2 molecules. Reprinted with permission from [306]. Copyright (2023) American Chemical Society. (b) Fabrication process of the HTL using different vacuum deposition techniques, including the control, SD, and MISD. [307] John Wiley & Sons. © 2023 Wiley-VCH GmbH. (c) Chemical structure of b-CD. Reproduced from [308] with permission from the Royal Society of Chemistry. (d) Structure of uracil. [266] John Wiley & Sons. © 2023 Wiley-VCH GmbH. (e) Si-substituted spirobifluorene hole-transporting material for PSCs. Reprinted with permission from [273]. Copyright (2023) American Chemical Society.

Figure 24. Schematic of PVK material degradation and overview of ISOS protocols for the properties of PVK materials and devices. Reprinted from [294], © 2023 Published by Elsevier Inc.

Figure 25. (a) Advantages of using GVL-based PVK precursor solution. Reproduced from [331], with permission from Springer Nature. (b) Pb(NO3)2 and PbI2 films were prepared from pure Pb(NO3)2 solution and PbCO3 NFs, respectively. Red and yellow arrows indicate mp-TiO2 substrates and Pb(NO3)2 films, respectively. Reproduced from [332] with permission from the Royal Society of Chemistry. (c) Schematic of crystallization under different relative humidity. Reproduced from [333] with permission from the Royal Society of Chemistry.

Figure 26. (a) Architecture of a semitransparent device with the TiO2 layer. (b) Pb concentration of PSCs with and without TiO2 (left) for 10 d in 10 ml of water. (a), (b) Reproduced from [345], with permission from Springer Nature. (c) Hunting mechanism of spider web from molecular composition to overall structure. (d) Pb SQEs of the damaged U-PSC, G-PSC, and BG-PSC in the Yellow River water. (c), (d) Reproduced from [346]. CC BY 4.0. (e) Schematic of lead capturing by crosslinking HPβCD-BTCA supramolecular complex. (f) Comparison of Pb sequestration for the damaged PSCs with or without HPβCD-BTCA. (e), (f) Reproduced from [347], with permission from Springer Nature.

Table 1. Summary of the performance of two-terminal PVK-based tandem solar cells.

Voc Jsc FF PCE Type Structure (V) (mA cm−2) (%) (%) References PVK/silicon Ag finger/MgF2/IZO/SnO2/PDAI/LiF/C60/PVK/2PACz/IZO/nc-Si(n)/a-Si(i)/c-Si/a-Si(i)/IZO/MgF2/Ag 1.949 20.9 80.5 32.8 [186] Ag contact/LiF/IZO/SnO2/PI + C60/PVK/2PACz/TCO/Si heterojunction 1.98 20.24 81.18 32.5 [187] Ag finger/MgF2/IZO/SnO2/C60/PVK/Me-4PACz/ITO/nc-SiH(n+/p+)/a-SiH(i/n)/c-Si/a-SiH(i)/nc-Si:H(p)/ITO/Ag 1.91 20.47 79.8 31.25 [188] Ag finger/MgF2/IZO/SnO2/C60/PVK/NiO/MeO-2PACz/ITO/a-Si:H(i/n)/c-Si(n)/a-Si:H(i/p)/ITO/Ag 1.941 20.1 76.6 29.8 [197] Ag finger/LiFx/IZO/BCP/C60/PVK/MeO/poly-Si(p+)/poly-Si(n+)/SiOx/c-Si/SiOx/poly-Si(p+)/Cr/Ag 1.83 19.7 81.0 29.2 [198] PDMS/Ag/IZO/SnO2/C60/PVK/HTL/ITO/a-Si:H(n)/a-Si:H(i)/c-Si/a-Si:H(i)/a-Si:H(P)/ITO 1.86 19.77 79.38 29.25 [199] Ag finger/MgFx/IZO/BCP:Ag/C60/PVK/IZO/SAM/poly-Si(n)/SiOx/c-Si(n)/SiOx/poly-Si(p)/Cr/Ag 1.85 19.4 81.8 29.3 [200] PVK/PVK ITO/NiO/SAM/WBG PVK/C60/SnO2/Au/PEDOT:PSS/NBG PVK/C60/BCP/Cu 2.112 16.5 81.9 28.5 [189] FTO/NiOx/Me-4PACz/WBG PVK/C60/SnOx/Au/PEDOT:PSS/NBG PVK/C60/SnOx/Ag 2.14 15.6 84.0 28.1 [191] ITO/NiO/SAM/WBG PVK/C60/ALD-SnO2/IC-CH/NBG PVK/C60/ALD-SnO2/Cu 2.11 16.7 79.5 28.1 [201] ITO/NiOx-SAM/WBG PVK/C60/ALD-SnO2/ITO NCs/NBG PVK/C60/ALD-SnO2/Cu 2.135 16.2 81.5 28.1 [202] ITO/2PACz/WBG PVK/C60/ALD-SnO2/Au/PEDOT:PSS/NBG PVK/C60/BCP/Cu 2.11 16.02 82.2 27.84 [190] ITO/SAM/WBG PVK/C60/SnO2/IZO/PEDOT:PSS/NBG PVK/C60/SnO2/Cu 2.11 15.37 83.13 27.01 (1 cm2) [203] PVK/organic ITO/Cl@MZO/CsPbI2Br/PM6/MoO3/Ag/PFN-Br/PM6:BTP-eC9/MoO3/Ag 2.152 13.89 80.57 24.07 [204] ITO/NiOx/2PACz/FA0.8Cs0.2Pb(I0.5Br0.5)3/C60/BCP/Au/MoOx/PM6:PM7:Y6:PC71BM/C60/BCP/Ag 2.14 14.17 80.71 24.47 [192] FTO/c-TiO2/mp-TiO2/CsPbI2.2Br0.8/PTACl/PBDB-T/MoO3/Ag/ZnO/PDIN/PM6:Y6:PC61BM/MoO3/Ag 2.11 13.65 80.1 23.07 [205] ITO/MeO-2PACz/FA0.8Cs0.2Pb(I0.6Br0.4)3/C60/CC1-P/ITO/MoO3/PM6:BTP-eC9:PC71BM/TPMA/Ag 2.09 14.58 78.99 24.07 [206] ITO/ZnO/SnO2/MAFm/CsPbI2Br/MAFm/PDCBT/MoO3/Au/ZnO/BCP/PM6:CH1007/MoO3/Ag 2.10 14.23 77.70 23.21 [207] ITO/4PADCB/FAMACsPb(I0.5Br0.5)3/C60/SnO2/Au/MoO3/PM6:BTP-eC9:PCBM/PNDIT-F3N/Ag 2.197 14.15 77.6 24.12 [193] Table 2. Summary of the performance of four-terminal PVK-based tandem solar cells.

Type Structure Top cell PCE (%) Bottom cell PCE (%) Total PCE (%) References PVK/silicon Top: ITO/SnO2/PVK/Spiro-OMeTAD/MoO3/IZO/Au 22.6 7.7 30.3 [194] Bottom: PERL silicon cell Top: ITO/SnO2/ZnO/PVK/Spiro-OMeTAD/MoO3/ITO 19.15 9.68 28.83 [208] Bottom: TOPCon silicon cell Top: ITO/MeO-2PACz/PVK/C60/BCP:Ag/IZO/MgFx 19.2 9.2 28.4 [209] Bottom: TOPCon silicon cell PVK/PVK Top: ITO/MeO-2PACz/1.66 eV PVK/C60/SnO2/ITO 20.13 7.93 28.06 [195] Bottom: ITO/PEDOT:PSS/1.25 eV PVK/C60/BCP/Cu Top: ITO/MeO-2PACz/PVK/C60/SnO2/ITO 19.82 7.25 27.07 [210] Bottom: ITO/PEDOT:PSS/1.25 eV PVK/C60/BCP/Cu Top: ITO/DCB-BPA/1.77 eV PVK/C60/SnO2/IZO 17.87 9.03 26.9 [211] Bottom: ITO/PEDOT:PSS/1.25 eV PVK/C60/BCP/Cu PVK/CIGS Top: ITO/NiOx/PVK/C60/SnOx/ITO/LiF 21.8 7.3 29.9 [196] Bottom: Mo/CIGS/CdS/i-ZnO/ZnO:Al Top: ITO/poly-TPD/PVK/C60/SnOx/IZO 19.1 9.3 28.4 [212] Bottom: Mo/CIGS/CdS/i-ZnO/AZO PVK/organic Top: ITO/SnO2/ZnO/CsPbI2.25Br0.75/PTAA/MoO3/ITO 15.52 6.82 22.34 [213] Bottom: ITO/PEDOT:PSS/D18-Cl-B:N3:PC61BM/PDIN/Ag Table 3. Summary of the device stability research progress.

PVK composition Structure Max PCE Condition Stability Strategy References Rb0.05Cs0.05MA0.05FA0.85Pb(I0.95Br0.05)3 p-i-n 25.5% 25 °C-85 °C; white light-emitting diode at 1.2 sun; and 85% RH <8% degradation after approximately 2560 h; >1000 h at 85 °C Improving the ion-blocking properties of the self-SAM HTL [81] FA0.85Cs0.15Pb(I0.95Br0.05)3 p-i-n 22.26% 75 °C; 1 sun-equivalent white-light LED 93% of the initial efficiency of the device retained after continuous operation for 1000 h Modulation of PVK decomposition with a robust Bi/Al2O3/parylene multibarrier [312] CsMAFAPbI3 p-i-n 21.91% 55 ± 5 °C; AM 1.5 illumination; and in the air. The encapsulated device retained 81% of its original PCE after 1000 h Synthesized a crosslinked fluoropropyl methylsiloxane-dimethylsiloxane multiblock polymer (CFDP) with good thermal stability [299] FA0.9Cs0.1PbI3 p-i-n 24.1% 85 °C; simulated AM 1.5G illumination; and in an N2 atmosphere Maintained 90% of the initial efficiency after ∼1500 h Ammonium cation, PEAMA+, with a high acid dissociation constant (pKa) [267] FA0.79MA0.16Cs0.05PbI3 p-i-n 22.5% 85 °C; 1-sun illumination; and 50% RH The device showed superior stability with almost no efficiency loss after MPP tracking at 85 °C for 2000 h The ‘physical’ passivation method by producing AlOx interlayers grown by ALD at the PVK/charge extraction layer heterojunction [268] Cs0.05(MA0.17FA0.83)0.95Pb(I0.83Br0.17)3 p-i-n 19.12% UVO: ultraviolet photons in the wavelength range of 200 nm The devices retained their initial PCEs of 17.0% after 20 min of exposure A silicon oxide barrier layer [313] (AA)2MA4Pb5I16 p-i-n 18.55% 30 °C-40 °C; LED illumination (AM 1.5G, 100 mW cm−2); and under a N2 environment. The device decayed slowly and maintained 80% of its initial PCE after 400 h Introduced CH3COOH(HAc) as a cosolvent [297] FAPbI3 n-i-p 21.42% 70 °C; in the dark; and N2 environment. The devices had 2% efficiency loss at 70 °C Developed a strategy of doping m-MTDATA HTLs with MoO3 [275] (FAPbI3)x(MAPbBr3)1−x n-i-p 22.5% At ambient temperature; under 1-sun illumination; and in an Ar atmosphere The PSC retained 92.9% of its initial PCE after continuous light illumination for 120 h The center carbon of Spiro-MeOTAD was substituted with a Si atom [273] CsPbI3−xBrx n-i-p 20.59% 25 °C; Newport solar simulator (94 043 A) with an AM 1.5G spectrum, light intensity: 100 mW cm−2; and 25% RH When the devices were aged for 3055 h, the optimized PSCs retained 91% of their initial PCE A TrMAPbX3 (X = Br and I) PVK with a linearly rotatable skeleton was synthesized [302] 0.97(FAPbI3) 0.03(MAPbBr3) n-i-p 23.22% 28 °C; under AM 1.5G 1-sun (100 mW cm−2) illumination; and 30% RH. The device maintained 87% of its initial PCE after 2000 h An efficient passivation material (K2-PDT) was developed [314] Cs0.05FA0.95PbI3 p-i-n 24.29% Room temperature; 1-sun illumination; and an inert atmosphere The device maintained 75% of its initial PCE for up to 450 h (thermal stress and operational stability) Compositional engineering using a single Cs-doped crystal [178] FA0.9Cs0.1PbI2.8Br0.2 n-i-p 23.17% 100 mW cm−2, white LED and N2 atmosphere Devices maintained 89.7% of their initial PCEs Molecular engineering of nanographene-based HTMs and interface modifiers [315] CsPbI1.5Br1.5 p-i-n 4.25% At room temperature; under AM 1.5G light; and in an ambient atmosphere CsPbI1.5Br1.5 retained approximately 90% PCE under 1 sun AM 1.5G illumination for 12 h Polyvinylpyrrolidone (PVP) polymer-assisted in situ crystallization [316] Cs0.09FAI0.91PbI3 n-i-p 20.26% 75 °C; 1 sun-equivalent illumination; and nitrogen environment PSCs retained >80% of their original PCE after an operando stability test at 200 h and 75 °C Infiltration of TiOx via vapor-phase infiltration (VPI) [280] (FA0.83MA0.17)0.95Cs0.05Pb(I0.83Br0.17)3 p-i-n 20.67% 1-sun illumination and 40%-50% RH The unencapsulated device retained 95% of PCE after 3000 h A mixing engineering strategy that combined Me-4PACz SAM with conjugated polyelectrolyte PFN-Br [272] (FAPbI3)0.97(MAPbBr3)0.03 n-i-p 24.0% 40 °C; continuous 1-sun illumination; and in N2 environment. Device retained 88% of its initial PCE after 2000 h at 40 °C and 1-sun illumination Bifunctional aromatic ligands [306] CsPb0.6Sn0.4I3 p-i-n 16.79% 1 sun illumination (100 mW cm−2) and in an N2-filled glovebox The device retained 90% retention of its initial PCE after 958 h under continuous illumination A surface Sn (IV) hydrolysis (SSH) method [264] Sn PVK p-i-n 12.1% In dark and an N2 atmosphere After dark storage measurements (∼2800 h), the PCE increased from 6.4% to 7.5% Surface modification of PEDOT:PSS with aromatic diammonium acetate [150] CsCl-FAPbI3 n-i-p 23.20% 25 °C and under 45%−65% RH The device maintained 60% of its initial PCE after 1056 h Residual chlorides were eliminated by post-heat treatment (PHT) [317] FA0.6MA0.4PbI3 p-i-n 23.1% 1-sun (AM 1.5G) illumination and in a nitrogen-filled glovebox The SC-PSC lost approximately 25% of its initial PCE after ∼730 h of MPPT Hydrophilic SAM MeO-2PACz HTL [177] (Cs0.05FA0.80MA0.15)Pb(I0.95Br0.05)3; FAPbI3 n-i-p 23.50% and 24.61% 1 sun illumination PCE stabilized at 23.63% initially and then decreased to 23.23% after 300 s at a constant potential and maximum power The organic salt of bidentate imidazole [298] Cs0.05MA0.85FA0.10Pb(I0.97Br0.03)3 n-i-p 22.92% At room temperature; 100 mW cm−2 simulated AM 1.5G irradiation; and 65 ± 5% RH Approximately 88% of initial PCE was retained after aging 2900 h A spontaneous internal encapsulation strategy by constructing a dual interfacial PVK heterojunction at the top and buried interfaces of the 3D PVK film [318] FA0.9MA0.03Cs0.07PbI2.76Br0.24 n-i-p 22.3% AM 1.5G illumination and in ambient conditions with 30% RH Retained >90% of the initial PCE after 5200 h A molecular implantation-assisted sequential doping (MISD) approach [307] FAMACsPb(ICl)3 n-i-p 24.23% 40 °C-50 °C; an LED array with an intensity of 100 mW cm−2; and in a box with continuous N2 flow Maintained >90% of its initial PCE after tracking at its MPP for ∼6000 h Introduced uracil as a bifunctional additive into PVK films [266] FA0.95Cs0.05PbI3 p-i-n 23.91% White LED illumination (100 mW cm−2) and in a nitrogen atmosphere The devices maintained >93% of their initial PCEs after 1680 h of MPP tracking In situ chemical crosslinking of the polymer TFEMA [310] FAPbxSn1−xI3 p-i-n 23.7% 50 ± 5 °C; 1-sun illumination; and in air Retained 88% of its initial PCE for 1000 h Tailored octylammonium tetrafluoroborate (OABF4) additive [319] Rb0.05Cs0.05(FA0.83MA0.17)0.95Pb(I0.83Br0.17)3 n-i-p 21.95% Room temperature; 1-sun illumination; and N2 atmosphere Almost no degradation after >1000 h of MPP tracking Functionalized 2D titanium carbide (Ti3C2) MXene [274] MAPb(I1−xBrx)3 p-i-n 21.23% 85 °C and in a nitrogen atmosphere 80% of the initial PCE was reached after >3500 h A simplified dual-source vacuum deposition method [320] Cs0.05MA0.15FA0.8Pb(I0.75Br0.25)3 n-i-p 24.12% 20 °C and in dry air (RH: 10%-20%) The devices maintained >90% of their initial PCE after 8000 h A uniform polymer internal package layer constructed using thermally triggered cross-linkable monomers [279] Cs0.05(MA0.17FA0.83)0.95Pb(I0.83Br0.17)3 p-i-n 15.26% 20 °C and 40% RH Maintained 75% of the initial PCE after 600 h Evaluated the effectiveness of oxygen, sulfur, and selenium-based interface passivator molecules [295] (CsPbI3)0.05[(FAPbI3)0.90(MAPbBr3)0.10]0.95 p-i-n 20.64% In ambient environment with 45% RH Retained 80% of its PCE after 350 h The use of polyoxometalate complex [(C8H17)4N]4 [SiW12O40] (TOASiW12) as the cathode layer [277] FA0.95Cs0.05PbI3 p-i-n 24.5% 40 °C; 1-sun illumination and in N2 atmosphere Initial PCE of ∼23% and stabilized at ∼23.5% for >3500 h Lewis base diphosphine molecule of 1,3-bis(diphenylphosphino)propane (DPPP) [294] MAPbI3 p-i-n 20.55% Ambient air and 30% relative humidity After 1900 h, the device maintained 89% of its initial PCE By incorporating a natural 1D material, ethyl cellulose (EC), within the PVK films [311] PVK-PbI2 heterojunction n-i-p 24.23% 65 °C; continuous AM 1.5G illumination (100 mW cm−2); and N2 atmosphere No obvious PCE degradation after illumination aging for 200 h A high-quality PVK-PbI2 heterojunction film was constructed [265] FAxMA1−xPbI3 n-i-p 18.76% 30 °C and 80% relative humidity. The PSCs maintained 95% of their initial efficiency after 2400 h An organic-inorganic hybrid material (AlxOyCz) was grown by plasma-enhanced MLD (PEMLD) [281] FAxCs1−xPbI3 n-i-p 24.26% 25 ± 5 °C and under 1-sun illumination; Maintained 94.7% of their initial efficiencies after operating for 1000 h A pre-embedding mixed A-cation halide strategy [305] FAPbI3 n-i-p 24.7% 85 °C and AM 1.5G conditions After 500 h of aging, the cells exhibited an average PCE retention rate of 92% SBF-FC hole-transporting material, with a high glass-transition temperature [276] Cs0.05FA0.95PbI3 p-i-n 23.2% 25 °C; ISOS-L-1; and in the N2 glovebox PSCs retained 91.8% of the highest efficiency after MPP tracking for 1000 h By introducing β-cyclodextrin (β-CD) iodine trapping agent [308] FAPbI3 n-i-p 25.0% 85 °C; under N2; and 60 ± 10% relative humidity Retained >92% of their initial efficiency for 1000 h Introduced alkylammonium formates (AAFos) [260] HA2PbI2Br2 passivated FACsPbI3 PVK n-i-p 24.29% 1-sun illumination and a nitrogen atmosphere Retained ∼93% of its initial PCE after 1000 h Developed HA2PbI2Br2-passivated FAC-based PVK [259] -